Classic roller-ring grinding mill for minerals

Raymond Mill

-

15 - 250 Kw

Power

-

1 - 45 t/h

Capacity

Description: Raymond mill is mainly used to grind non-inflammable and non-explosive materials with Moh’s hardness below 7 and moisture content below 8% such as limestone, barite, calcite, talc, calcium oxide, quartz, feldspar, calcite, etc. it can provide fineness fro

Model: 3R2115

Roller Qty: 3

Capacity: 0.5-1.8 t/h

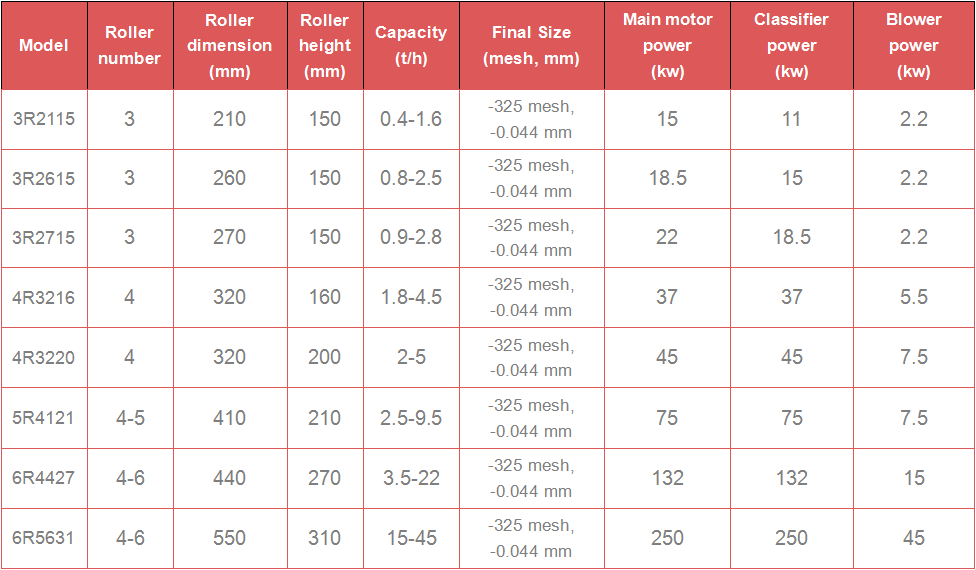

Raymond mill is the most commonly used roller-ring grinding mill system worldwide to grind mineral materials into 80-325 mesh fine powder, such as limestone, calcite, feldspar, calcium carbonate, dolomite, kaolin, bentonite, etc. It has several rollers and a grinding ring in its grinding chamber as the main grinding structure to grind material into powder and on the top part of the machine it has a classifier to select fine powder and control the fineness.

Raymond mill mineral powder production line video

II. Features of raymond mills:

High ruturn on investment:

The price for a raymond mill and its infrustructure costs are comparably lower than other mill, at the same time, its output is pretty good from 2tph to 45tph, and fineness from 80 mesh to 325 mesh, if it is equipped with a cage-type classifier, it can even reach 400+ mesh. Also its installation is easier and cost less time.

Small area required:

Raymond mill is a vertical type grinding mill, comparing to ball mill, raymond mill only requires about half of area.

Highly automatic:

Raymond mill integrates grinding, classifying, powder collecting, fineness controlling in one machine, enable it to become highly automatically controlled by a PLC system.

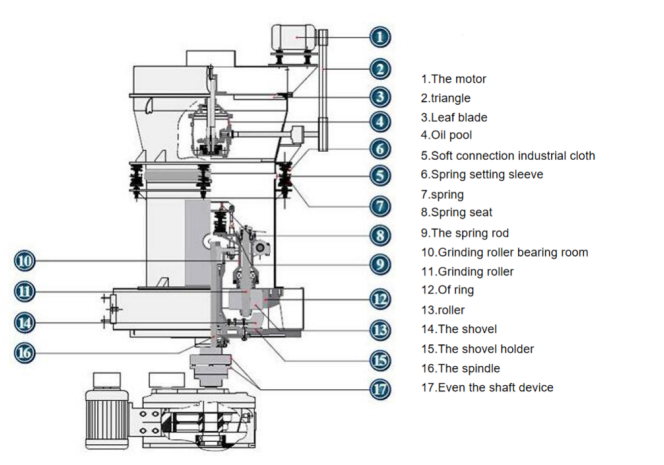

III. Raymond mill working process and main structures

1. The material is evenly and continuously fed into the main grinding chamber of the Raymond mill.

2. Due to the centrifugal force during rotation, the grinding roller swings outward, pressing the grinding ring tightly, and the scraper scoop up the material and sends it to the space between the roller and the ring. With the roller rotate in high speed, the material is ground into powder.

3. After grinding, strong air flow from the blower will send powder material into the classifier for powder selecting, powder that reach the required fineness will pass through the classifier and is collected as final product, powder that doesn't reach the required fineness will return to grinding chamber for re-grinding.

2. Raymond mill main structure

V. Improved model of Raymond mill - MTW series European type grinding mill

Introduction:

MTW series grinding mill, also named European type industrial trapezium mill, is a new type of mineral powder grinding mill based on raymond mill.

Comparing to raymond mill, its features are:

1. Roller assembly get longer service life, much lower failure rate and costs much less time to do the maintenance.

2. Final product particle size distribution is very uniform, meeting high quality standard.

3. Lower vibration, lower noise and more efficient transmission, making the whole system longer service life and stable running performance.

Click here to see MTW series grinding mill details→

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat