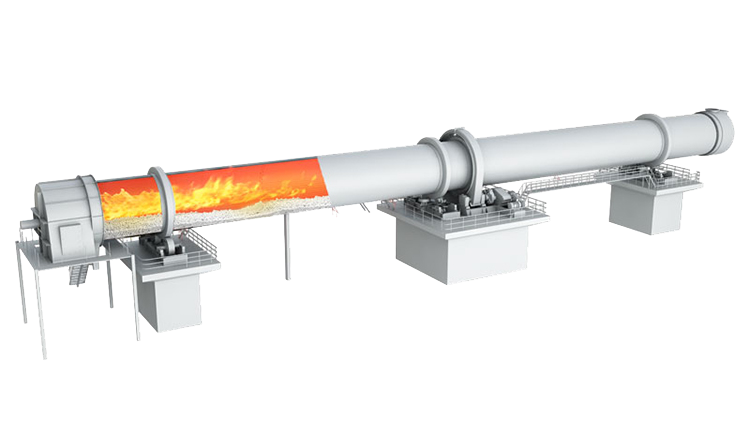

rotary kiln for cement clinker calcination

Cement rotary kiln

-

120-680 kw

Power

-

200-6000 tpd

Capacity

Description: Rotary kiln is the key and crucial equipment for cement clinker production, it features high capacity, high reliability and long service life, with latest design, it has high efficiency preheater, coal powder burner and dust collector, enable the cement p

Model:

Capacity: 200tpd

1. Introduction of the cement rotary kiln

Cement rotary kiln is the key equipment in cement production and plays a decisive role to the quality of cement. It features high capacity, high reliability and long service life, with latest design, it has high efficiency preheater, energy saving coal powder burner and super-clean dust collector, enable the cement production line energy saving and environmental friendly.

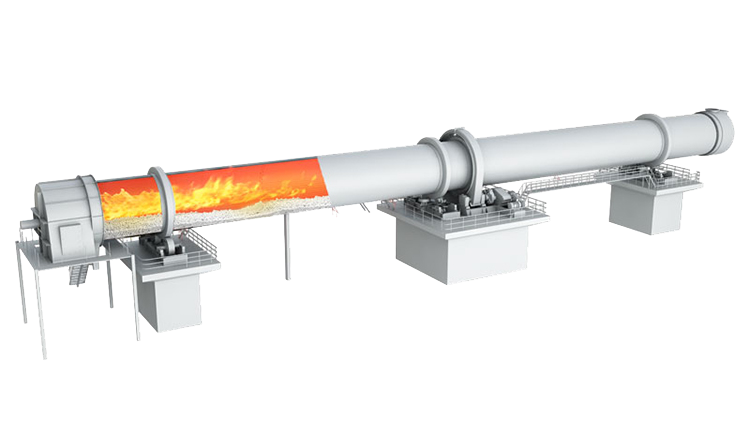

2. Working principle of a cement rotary kiln

Cement clinker calcination is the process of calcining cement raw materials (limestone, clay and gypsum)into cement clinker at high temperatures, which is an important production process in the classic cement production known as: "two grinding and one calcination" (i.e. raw material grinding, clinker calcination, and cement grinding).

The rotary kiln is high at one end and low at the other end, with high-end feeding, low-end discharge, and coal feeding. During the continuous rotation process, the calcination of clinker is completed in the kiln.

The material enters the kiln from the kiln tail (high-end), and due to the tilting and slow rotation of the kiln shell, the material rolls along the axial and radial directions and gradually moves forward.

Fuel is sprayed into the kiln from the low end through a burner for combustion, and heat is transmitted to the material through radiation and conduction. During the movement of the material, a liquid phase is generated, generating minerals such as tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium ferroaluminate. After sintering, clinker is generated, and then discharged from the kiln head.

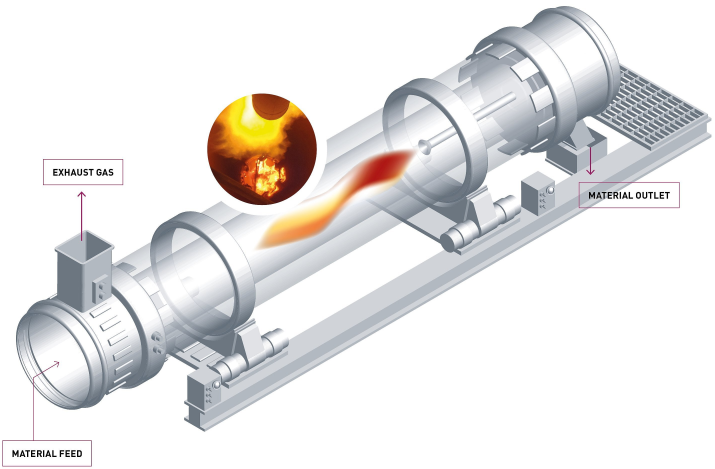

3. Auxiliary equipment of a cement rotary kiln

During the operation of the cement kiln, equipment such as coal burner, preheaters, coolers, and dust collectors are required to cooperate with its work.

The preheater is used to preheat and partially decompose materials, enabling better utilization of heat.

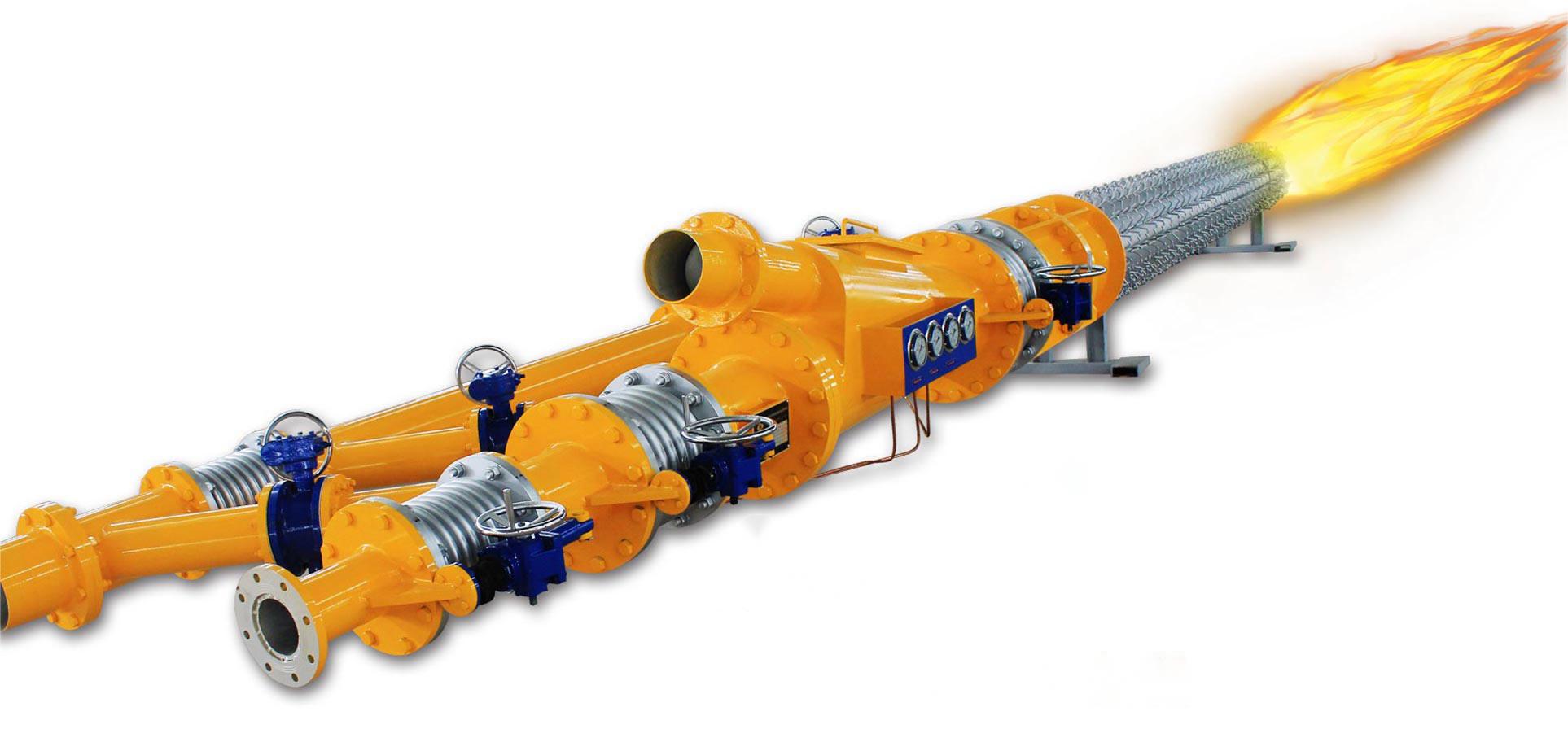

The burner is used to burn coal powder or natural gas to provide heat to the rotary kiln system.

The dust collector is used to treat the dust and smoke generated during the material calcination process, ensuring that the dust emission meets national requirements.

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat