Large-scale Calcination Equipment

Rotary Kiln

-

55 - 560 KW

Power

-

180 - 5000 t/d

Capacity

Description: Rotary kiln is applicable for calcination for : magnesium oxide, cement, zinc oxide, titanium dioxide, ceramsite sand, bauxite, gypsum, limestone, bauxite, alumina, nickel ore, kaolin, etc.

Model: φ2.5x40m

Motor Power: 55 KW

Capacity: 180 t/d

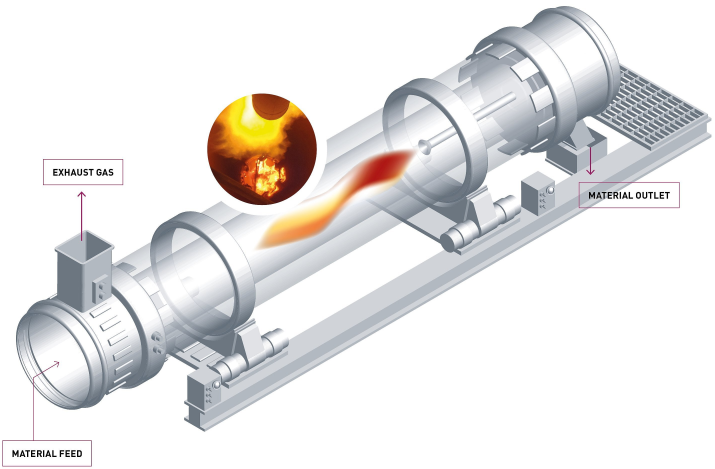

I. What is a rotary kiln system?

A rotary kiln is an industrial furnace used to process materials at high temperatures, typically for cement, lime, and mineral production. Its cylindrical, rotating design ensures even heat distribution, enabling efficient chemical reactions and material transformation in cement and mineral processing industries.

Laterite nickel ore calcinating rotary kiln plant

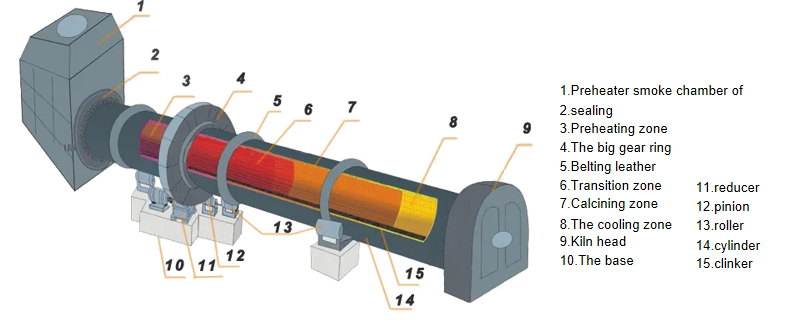

II. Rotary kiln working process and main structure

*Rotary kiln is composed of cylinder body, supporting device, retaining wheel supporting device, transmission device, kiln tail sealing device

1. When a rotary kiln is running, a main drive motor transmits power to the gear device through the main reducer to drive the rotary kiln.

2. The material enters the kiln from the kiln tail (the higher end of the cylinder) . With the inclination and slow rotation of the cylinder, the material rolls in the circumferential direction and moves from the higher end to the lower end, and the raw clinker enters the cooler for cooling through the kiln head cover.

3. The high-temperature calcining gas is injected into the kiln from the kiln head, and the waste gas produced by combustion is discharged with the material, and then discharged from the kiln tail.

III. Contact us for quick quotation and project design!

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat