Minerals and bio products drying equipment

Rotary dryer

-

7.5 - 200 kw

Power

-

2.5 - 100 t/h

Capacity

Description: Rotary dryer is the univeral industrial drying equipment for minerals and bio products such as sand, quartz, silica sand, coal, gypsum, limestone, active carbon, palm fiber, wood chips, wood sawdust, chicken manure, etc.

Model: Φ1.2*10m

Main motor: 7.5kw

Capacity: 2.5t/h

Introduction of a rotary dryer

The rotary dryer is a very mature drying equipment suitable for drying various materials in various industries such as ore, bio-products, mineral powder, coal, sludge and metal and non-metallic minerals concentrates after ore beneficiation. Rotary dryer features high productivity and easy operation. Its main body is a horizontal rotating drum, with various shapes of plates and chains installed inside with specific angles. According to different customer needs, we can also arrange refractory matter as the rotary dryer lining. At the feeding inlet, door rings and screw plates are installed to prevent material backflow. It has the advantages of reasonable structure, high capacity, low energy consumption, and convenient operation.

Is rotary dryer the correct drying equipment for my material?

The configuration of rotary dryer has huge flexibility on the heating source, fuel, heating method, temperature and drying capacity, therefore it can basically dry all the material you have in industrial process such as followings:

1. Chemical, mining, metallurgical and other industries, such as silica sand, ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin, bentonite

2. Agriculture, bio-products, feed, and fertilizer industries, such as oil palm fiber, fish meal, starch residue, distiller's grains, medicinal residue, sugarcane residue, peat, organic fertilizer, sludge, food factory waste, organic fertilizer, inorganic fertilizer.

3. Dry powder and granular materials. Such as various crystals, lightweight calcium carbonate, activated clay, magnetic powder, graphite, inorganic slurry, clay, lime slurry, ore slurry, phosphorus slag, aluminum factory red mud.

Working principle of rotary dryer

The heating equipment of the dryer is activated to continuously heat the dryer drum, with a maximum temperature of 800 ℃. The material containing moisture enters the feeding inlet of the rotary dryer through a conveyor. The dryer drum continuously rotates to move the material continues forward. During the drying process, the material is continuously lifted and dispersed by the lifting blades set on the inner wall of the drum, enabling the material to fully contact high-temperature air for heat exchange and evaporation of moisture. After completing the drying treatment, the final product is discharged from the outlet of the dryer.

Applicable fuel for rotary dryer

We can arrange different fuel heating for your dryer machine based on the costs, materials, and ease of access.

Coal, natural gas, biomass particles, natural gas, liquefied gas, oil, and electricity can all be used as heating sources.

Heating method

1. Direct heating dryer

The material in the rotary dryer directly contacts with hot air and are dried through convective heat transfer.

Direct heating features fast drying speed, high thermal efficiency, and sufficient contact between hot air and material, with less dust.

For direct heating, we can arrange two types of heat flow for your dyrer: countercurrent and downstream based on the material features.

2. Indirect heating dryer

Indirect drying system is suitable for materials that cannot contact with the hot air generated from fuel.

Contrary to direct heating rotary dryer, an indirect heating dryer equipment drying process without direct contact between the hot air and the material, all the heat required is conducted through the dryer shell.

For an indirect drying system, we can offer to arrange center heating transfer or shell heating transfer.

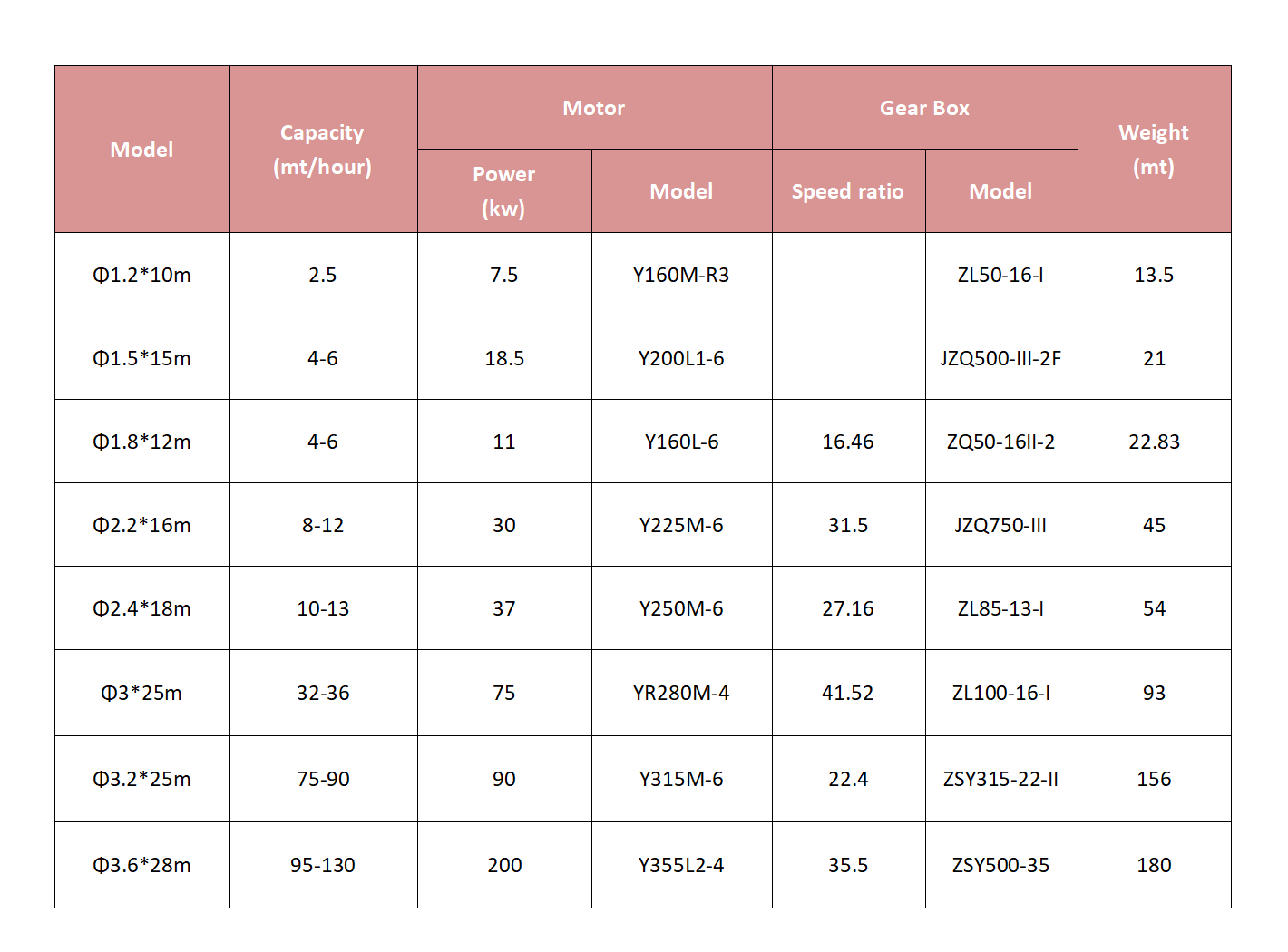

Specification and models of rotary dryer

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat