Gold mining CIP plant

![]() Processing Capacity: 100 t/d to 3000 t/d

Processing Capacity: 100 t/d to 3000 t/d

![]() Applied Equipment: Jaw crusher, Cone crusher, Ball mill, Thickner, Agitator tanks, Gold smelting furnace

Applied Equipment: Jaw crusher, Cone crusher, Ball mill, Thickner, Agitator tanks, Gold smelting furnace

![]() Applications: Extract gold from rock gold ore with 90% recovery rate

Applications: Extract gold from rock gold ore with 90% recovery rate

1. Introduction of CIP rock gold ore processing plant.

The CIP (Carbon in Pulp) gold extraction process refers to the process of gold ore crushing and gold ore grinding into slurry, followed by several physical and chemical processes to extract gold from ore slurry and makes it attainable for smelting furnace to get gold ingot.

The the CIP gold extraction process (carbon in pulp) has following features:

1. High recovery rate: the recovery rate using CIP plant can get 90%-93%, comparing with traditional amalgamation-flotation plant only about 70%-75%.

2. Low investment: CIP plant has less equipment and foundation construction required, and the reliability is very high and hardly cause troubles.

3. Few operators: the whole process can be highly automatically controlled by PLC system and the control is convenient and easy.

4. The active carbon can be recovered and recycled, and the recycled carbon can restore 95% of its ability of gold capture.

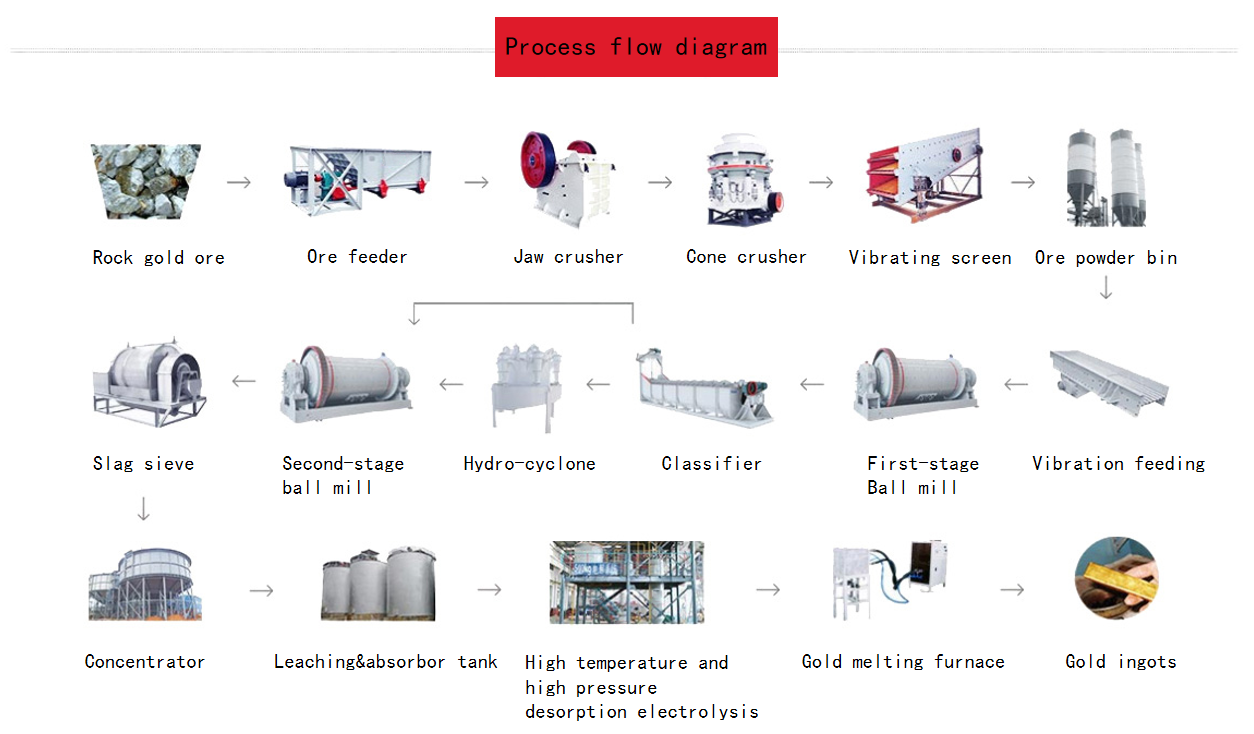

2. CIP production process and main equipment

The processes of CIP gold extracting plant is as followings:

1. Crushing of gold ore: rock gold ore will be crushed into small pieces under 10mm.

Main equipment: Jaw Crusher and Cone Crusher.

2. Grinding of gold ore: small piece of gold ore will be ground into ore slurry with 75 micron fineness.

Main equipment: Ball Mill

3. Ore slurry thickning: Gold ore fine particles are in the ore slurry, they will be separated from water and get concentrated.

Main equipment: Ore Slurry Thickner

4. Leaching and adsorbing: fine gold particles will first be dissolved into reagent and then carptured by active carbon.

Main equipment: Agitator tank

5. Desorption electrolysis: gold-carring active carbon from leaching and adsorbing section will be processed by electric shocked and then in this section we can collect gold mud.

Main equipment: desorption electrolysis system

6. Gold smelting system: gold mud will be smelted in the smelting furnace and we can get god ingots

3. We can offer you turnkey experience for your gold mining project! The complete production line

If you are considering to set up a gold mining plant and looking for the machinery supplier, it is very tiring to search for the supplier one by one for each section of the complete production line. However, if you contact us, we can help you from begining to the end: we design the complete gold mining production line and we manufacture most of the machines in our own factory with high quality, and we will also help and instruct your people during installation and commissioning.

Please contact us for gold mining equipment! No matter the project is large scale or small scale!

Our rich experience and expertise is sure to help you a lot!

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat